Metals projects

About this project

I was initially introduced to fine metals projects largely through a special course taught through the material science department at MIT. I think that metal is a really cool medium to work in. Here are some of the projects I made!

Project information

- CategoryCourse project

- Project dateSpring 2022

- Skills usedMilling, lathe, CAD

Dragon Statue

For this project, I wanted to make a dragon statue for my sister because she was born in the year of the dragon and I thought it would be pretty cool to do it in metal.

Wax stamp

The wax stamp is made from an aluminum handle and a copper stamp that screws on. The handle started as a stock of aluminum rod which was turned on a CNC lathe to create the shape and the threads. The copper stamp was CNC milled to engrave the stamp design and tapped on the other side so it would screw into the handle. Copper has a higher thermal conductivity so it will cool the wax down faster and with the screw interface I’ll be able to make more stamps that are compatible with the handle in the future! In future iterations, I’ll improve fixturing so it doesn’t chatter as much during the facing operation or use a smaller facing tools and increases the number of passes.

Metal stamp

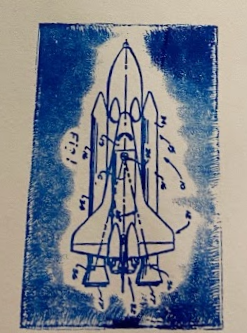

To make the etching in the metal, I printed an inverted rocket design on carbon transfer paper, transferred the carbon to the copper sheet, and placed the copper sheet in citric acid. The acid dissolved the metal everywhere except where the carbon resulting in the rocket engraving. Once the metal stamps were made, I used a rolling press to create a printing of the design on copper paper.

Ring

The ring is made from a sheet of copper which was embossed with my last name and then soldered together. After soldering, I hammered the metal back into the ring shape.