Arcturus

About this project

Arcturus is an Autonomous Marine Robotics Team that some friends and I founded in 2021. Over the last three years, our team has tripled in size reaching 60 active members, competed in 3 international competitions, and published a paper for the Oceans 2023 conference. As a team, our goal is to create a welcoming community for students to gain hands-on learning experience through building and programming autonomous vehicles. As the mechanical engineering lead, I’ve overseen the design and fabrication of mechanical systems on our competition boats: "Ship Happens," our primary vehicle from our first two seasons, and "Fish and Ships," our new flagship, which we aim to compete with in 2025.

Project information

- CategoryFor fun

- Project dateFall 2021- Spring 2024

"Fish and Ships" ( 2023 - Present)

Design

The main goals for "Fish and Ships" were to be lighter and smaller than "Ship Happens" to increase maneuverability in the water and ease of transport to and from testing. In 2023 our team decided to retire our boat Ship Happens and start designing our new boat using the knowledge we gained from the previous two years.

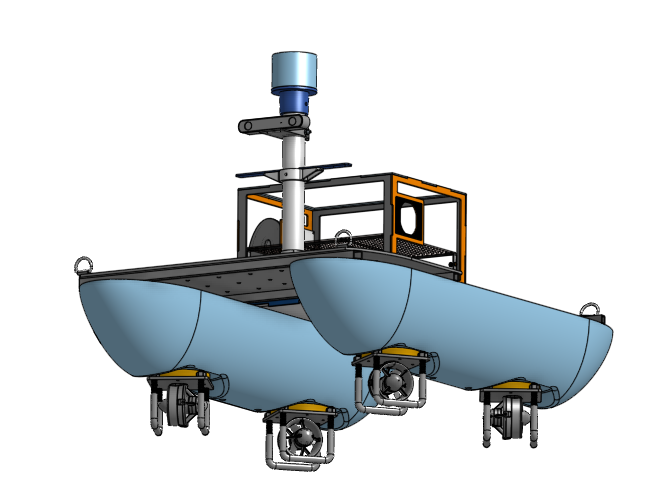

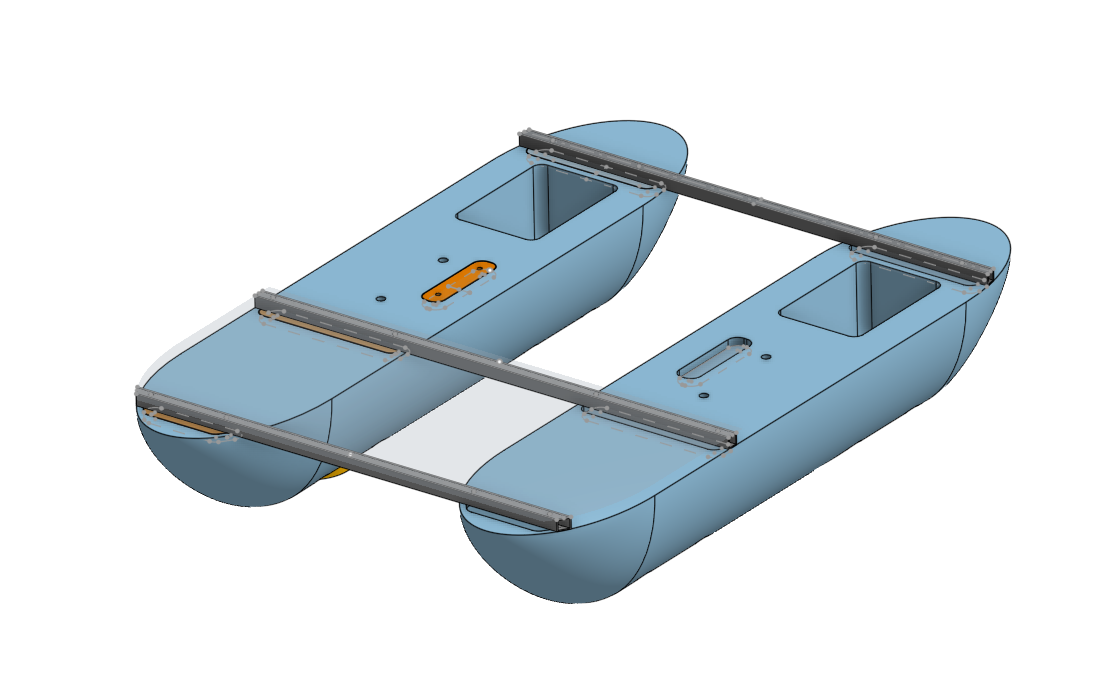

After researching, we decided on a catamaran because of its stability, speed, and energy efficiency. The hulls have a U-shaped cross-section to maximize the volume-to-surface area ratio and come to a point in the front and back to decrease drag. The hulls also have integrated plywood with T-nuts as hardpoints for mounting electronics, sensors, and thrusters, along with dedicated cavities for housing the batteries. Moving the batteries from above the hulls into the hulls decreases the overall boat dimension and increases the stability. The length and width of "Fish and Ships" are 48 in and 34 in respectively compared to 70 in and 30 in on "Ship Happens."

Manufacturing

The core of the hulls are made from layers of foam board which are CNC milled and stacked to create the final hull shape. The rigid foam interior ensures the boat will continue to float, even if punctured, unlike a hollow interior. For the outer layer, we cut a fiberglass sheet to fit the foam's outer surface, measured and applied epoxy to the sheet based on its weight, laid the soaked sheet over the foam, and placed it in a vacuum bag to remove excess epoxy. This was an improved version of the method used to create our first boat, where we covered the foam hulls with strips of fiberglass saturated with epoxy and let them cure in the air. The new hulls of Fish and Ships are 36 lbs each compared to the Ship Happens which were 47 lbs each.

"Ship Happens" (2021-2023)

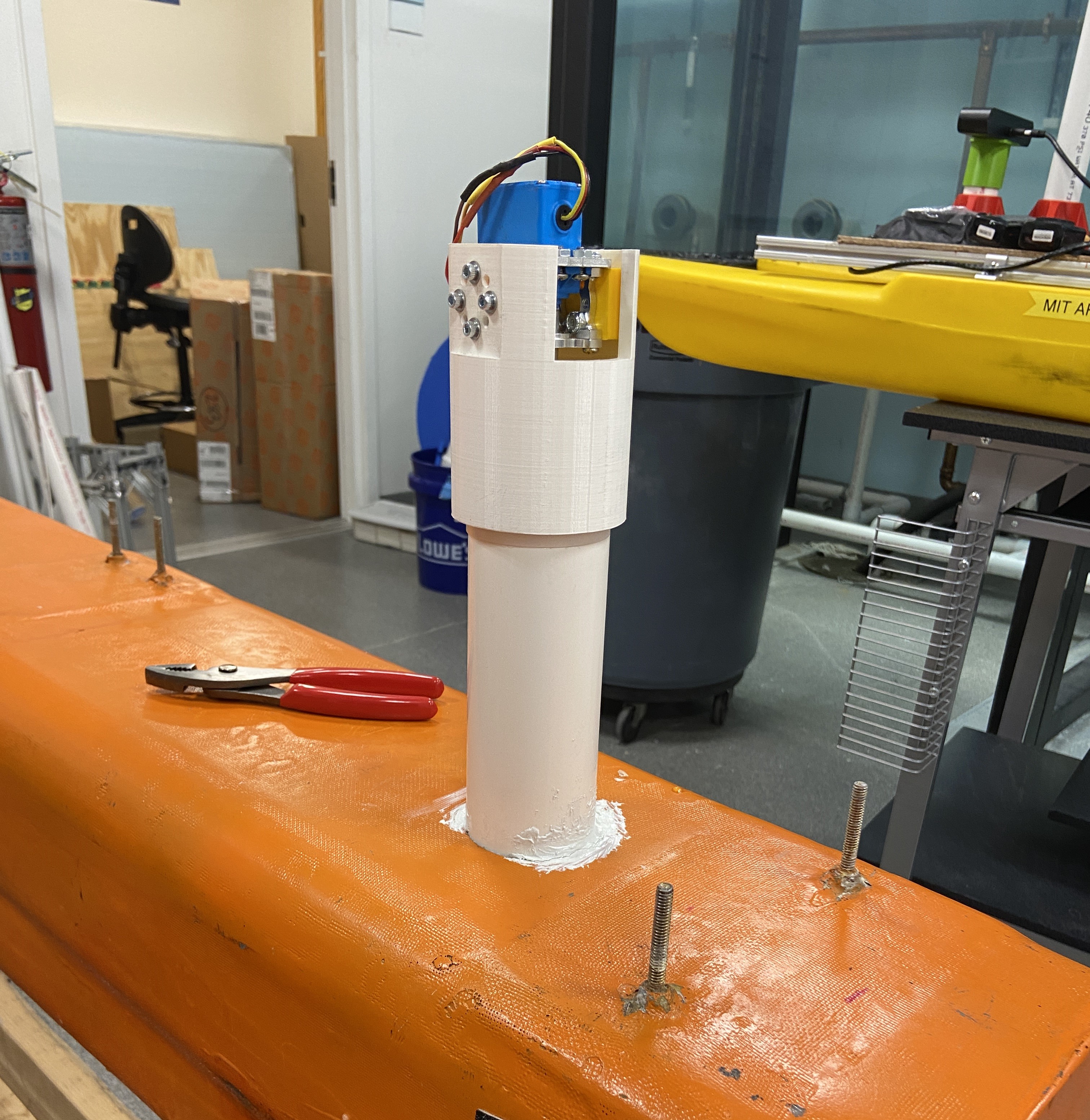

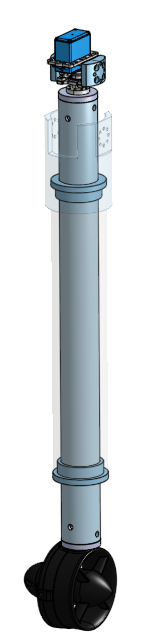

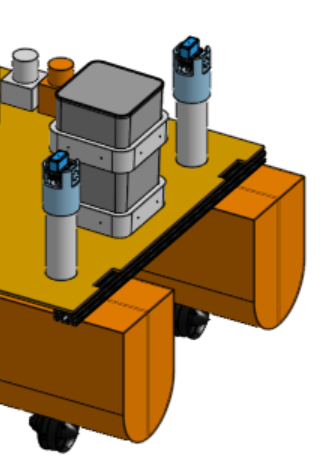

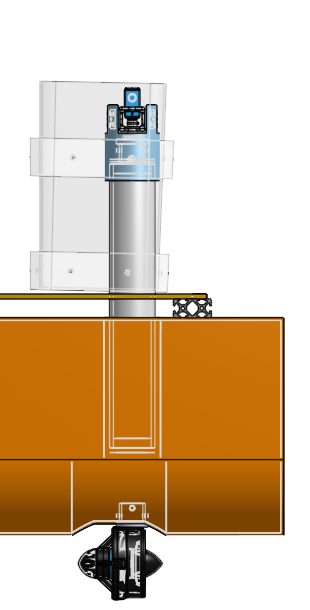

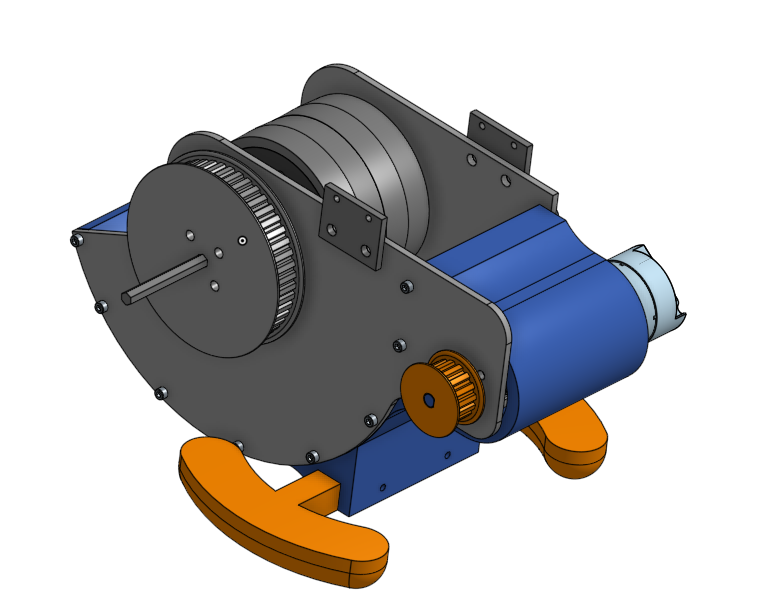

Azimuth Thrusters

To increase our maneuverability and prevent us from drifting into obstacles, we developed an azimuth thruster pod design that allows us to rotate our Blue Robotics T200 Thrusters in place. Each T200 thruster is attached to a servo motor through a PVC pipe, allowing us to reorient the thruster relative to the hull. The system is mounted inside a larger PVC pipe to create a telescoping mechanism, allowing us to lift the thruster into the hull during transport and deploy the thrusters in the water. To integrate the thruster pods, we drilled a vertical hole into the bottom of each hull, epoxied the PVC to the cavity, and resealed using fiberglass strips soaked in epoxy resin.

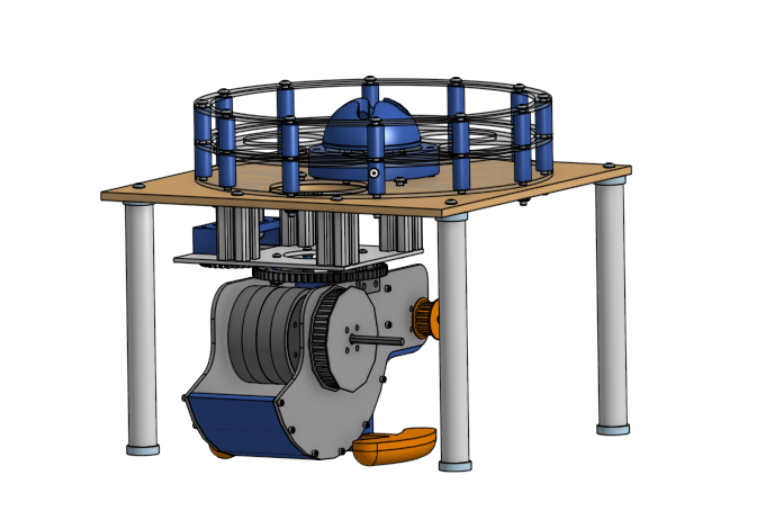

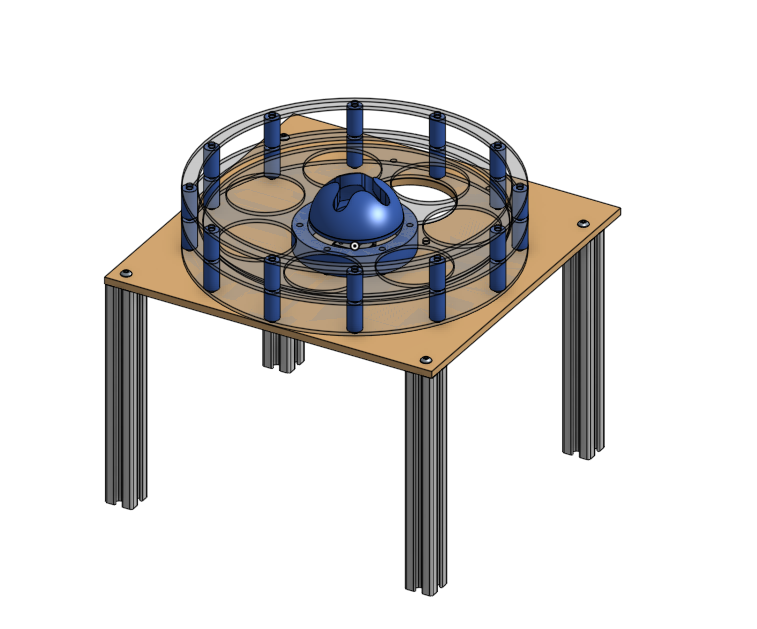

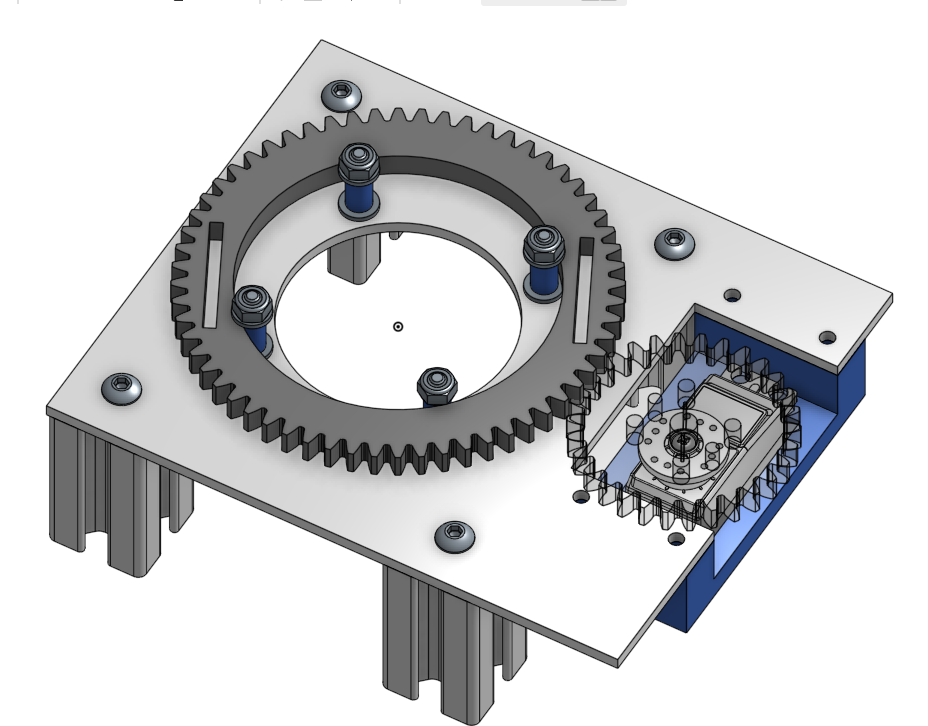

Ball Shooter Mechanism

For this challenge, our boat needed to shoot racquetballs into 5-gallon buckets around 8 feet away. Our launching mechanism consisted of 3 main parts: a rotating feeder, a turret, and a flywheel system. The rotating feeder holds up to eight balls and continuously rotates to drop them into the flywheel system. The flywheel consists of a series of rubber wheels that compress each racquetball, imparting spin before launching it. This entire shooting mechanism is mounted on a turret, which uses a servo motor to rotate the shooter independently from the rest of the boat, allowing for precise aiming and movement.

Water Gun

For this challenge, our boat needed to shoot water at a target to raise a ball. To increase the chances of hitting the target, we opted for continuous water flow by using a pump that draws water directly from the lake. The pump's output was connected to servos that control both yaw and pitch, allowing precise aiming of the water gun without requiring movement of the entire boat.